Ultra-Archaea® Supercharges Nature's Solution to Environmental Contamination.

They are 100% Natural, Hardy, and Fast-Acting Microbes that Eat Oil, Sludge, Grease, Algae, and More

Ultra-Archaea Shakers - Two Sizes

What is Ultra-Archaea?

Ultra-Archaea is an archaea-based collection of over one hundred different species of microbes that are collected from rugged environments such as undersea vents or sites where there is volcanic activity. They are then cultivated with crude oil as their only food source, ultimately thriving on thousands of organic compounds, from benzene to polycyclic aromatic hydrocarbons.

-

100% Natural: Non-genetically modified microbes

-

EPA National Contingency List: Featured on the EPA's list since inception

-

Effective for Oil and Organic Waste: Ultra-Archaea targets oil, grease, hydrocarbons, and organic pollutants

How Does Ultra-Achaea® Work?

Ultra-Archaea® microbes efficiently digest hydrocarbons and organic molecules, transforming them into harmless byproducts like carbon, carbon dioxide, and lipids. Introduced to contaminated areas, they rapidly multiply from billions to trillions per gram, remediating oil spills, grease traps, septic systems, and more. After depleting their food source, Ultra-Archaea® either die, return to natural levels, or are consumed by other organisms, allowing indigenous microbes to return to pre-contamination levels.

Microscopic View of Ultra-Archaea Eating Crude Oil

Ultra-Archaea®

Compared to Bacteria

Ultra-Archaea® and bacteria come from different life forms. Unlike bacteria, Ultra-Archaea® doesn't have receptors for viruses that can spread harmful genes. It thrives in extreme environments and can break down a wide variety of compounds, while bacteria usually focus on specific ones like alkanes.

Ultra-Archaea® is especially effective at cleaning up oil and hydrocarbons, making it a powerful tool for bioremediation. It’s 100% natural and comes from places like undersea vents, with no genetic modification.

Why Choose Ultra-Archaea®?

-

Natural – 100% naturally occurring and cultivated, non-GMO, non-pathogenic, non-freeze dried

-

Safe – Safe for use around people, plants, and animals—aquatic or land

-

Efficient – Five billion microbes per gram, doubles every 20 minutes to trillions

-

Effective – In many scenarios, drastically noticeable results appear within hours or days

-

Autonomous – Microbe colony declines after 90 days or without essentials, restoring native microbes

-

Versatile – Available in shaker form, tablets, booms, bags, and packets, all with a five-year shelf life

Proven Applications

-

Waste Water Treatment Plant — Industrial (refineries, pulp mills, chemical plants, steel mills, textile plants)

-

Waste Water Treatment Plant — Municipal (collection systems, food processing)

-

Plumbing Maintenance -(sinks, grease traps)

-

Spill Control

-

Septic Tanks

-

Odor Control

-

Bioremediation — (soil, water, storm water)

-

Agriculture/Aquaculture (eliminating ammonia, storm water)

-

Oily Water — (oil/water separators, containment sumps, lagoons)

-

RV and boat black water holding tanks

-

Bilges of boats

Ultra-Archaea®

A Cleaner, Greener Solution.

-

Fast-acting and efficient

-

100% natural, non-toxic solution

-

Eliminates odors within hours

-

Breaks down a wide range of hydrocarbons

-

Safe for aquatic life and ecosystems

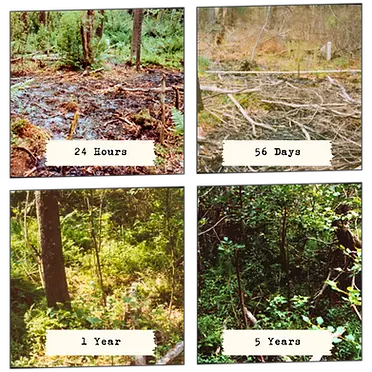

Case Study: Protected Wetlands

A leaking pipe in Halifax, MA poured thousands of gallons of kerosene into the wetlands, adjacent to cranberry bogs.

After the initial recovery of 38,000 gallons of surface kerosene, Ultra-Archaea® was used in the soil to clean the sensitive environment.

-

After 24 hours: Strong kerosene odor eliminated.

-

After 56 days: Contaminant levels reduced by 85%

-

After 1 year: TPH levels dropped from 310,000 ppm to 21,400 ppm

-

After 5 years: Full recovery with no detectible contaminants

Case Study: Sugar Production Plant

The world’s largest sugar production plant, located in Egypt, processes upwards of 2M lbs. of sugar beets per day and generates an estimated 1.2M gallons of wastewater daily.

In one of its primary lagoons, the plant needed to get chemical oxygen demand (COD) and biochemical oxygen demand (BOD) below 5,000 mg/L and 1,000 mg/L respectively.

Ultra-Archaea® was deployed to treat the wastewater, resulting in a 97-98% decrease in both COD and BOD over a six-week period. The water was then able to be used safely for irrigation—something that is extremely important in this desert region.

Contact Us for Purchasing Information

Or if we can answer any questions you may have.

+1 210.998.5799

Ultra-Archaea® Application Methods

1. Shakers - Two Sizes

-

Ultra-Archaea® is housed in a bentonite clay powder that provides the slightly moist environment needed for them to live.

-

Two sizes of shakers available for application on smaller spills or contained areas.

-

Resealable/waterproof containers keep microbes dry/dormant until they are needed.

2. Water Soluble Packets - Small Size, BIG Results

-

4 oz. water-soluble packets can be thrown into oil/water separators, catch basins, grease traps, and other areas to facilitate oil and grease removal.

-

No measuring, scooping, or spreading. Simply place the entire packet into the area that needs to be cleaned. The water-soluble packet will dissolve and allow the Ultra-Archaea to spread throughout the area.

3. Bulk Bags - For Large Spills

-

Bulk bags (25 lbs.) are available for large spills, open water applications, or frequent use areas.

-

Keep on hand for refilling Shakers or other smaller containers or for large, unexpected spills.

4. Tablets - 24 Tablets in each Tube

-

High concentration of Archaea (20 billion per gram)

-

Easy to break up and flush or drain – Simple to use

-

12-pack of tubes, 24 tablets per tube

5. Booms - Dimensions: 6″ x 4″ x 1″

-

Specially-treated polyethylene (LLDPE) foam used in Ultra-Archaea® Booms allows it to float on the water’s surface while also absorbing oil.

-

Microbe tablets (6) are inserted into slits in the foam sleeves — extended water contact causes the tablets to slowly dissolve, releasing the microbes into the water.

-

Booms can be dropped in, or tied off in catch basins (lanyards included), oil/ water separators or other areas where oily water can collect.

-

Sold in 6-packs.

Ultra-Archaea® microbes are microorganisms that have been collected from natural water and soil sources around the world. They are selected for their particular affinity for consuming hydrocarbon-based pollutants and organic material and are cultivated in a way that maximized the speed at which they consume these pollutants.

Part # | Model | Weight lbs (kg) | Quantity |

|---|---|---|---|

5232 | Water Soluble Packets (6 per box) | 1 (.5) | 1 Box of 6 Packets

|

5252 | 12-Pack | 1.5 lbs (0.7 kg) | 12-Pack (24 Tablets per Pack)

|

5234 | Mini Boo,, 6-Pack | 2 (.9) | 1 Box of 6 Booms |

5239 | Shakers | 2 (.9) | 1 Shaker |

5233 | Bulk Bag | 25 (11.3) | 1 Bag |

5257 | Bulk Bag - 90-billion, Sugar | 25 lbs (11kg) | 1 Bag |

5238 | Shakers | .5 (.2) | 1 Shaker |

Ultra-Archaea Frequently Asked Questions

Contact Information

18756 Stone Oak Pkwy #200

San Antonio, Texas 78258

info@fantailservices.com

+1 210.998.5799

DUNS: 118474034

CAGE: Code 98K03

Products

ANTI-MICROBIAL PROTECTION

KLEAN© Surface Protection

ASSET PROTECTION

Gentoo Coatings

Ultra-Rapid Boom

Sandless Sandbags

BIOREMEDIATION SOLUTIONS

Ultra-Archaea

CHEMICAL SOLUTIONS

DustAde®

Eliminator©

FireAde®

FireBull®

FIREFIGHTING

Fire Suppression

Fire Extinguishers

Training

One-on-One Coaching

Group Coaching

Workshop Facilitation

Keynotes & Seminars

Coach Leadership Program

Conflict Resolution

Presentation Skills Training